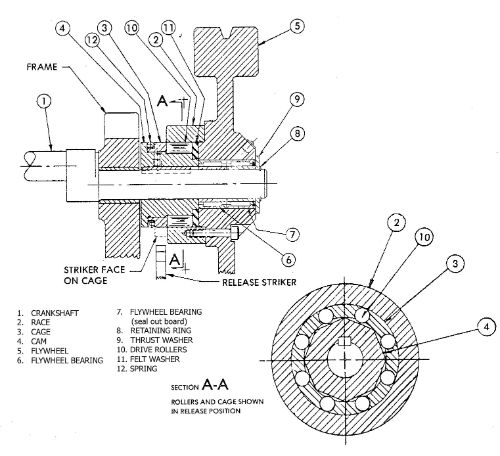

The roller clutch employs a principal of wedging a multiple of rollers between a driving member called the roller race and a driven member called the actuating cam. The cam is keyed to the crankshaft and the race is keyed to the flywheel. A spring loaded roller cage with a striking face machined on it moves the rollers from the other, controls the roller cage. When the solenoid is energized, it pulls up one end of the pivot arm, the wedge on the other end is pulled down. This allows the roller cage springs to move the cage and rollers to the wedging or driving position. Before the crankshaft has turned one revolution the solenoid is de-energized and the wedge is pulled up by the lever spring. When the cage striking face meets the release striker the cage is stopped. The crankshaft continues to rotate thus moving the rollers to the idle position where they do not wedge against the driving race. The flywheel will continue to turn but the crankshaft will stop near top-center position.

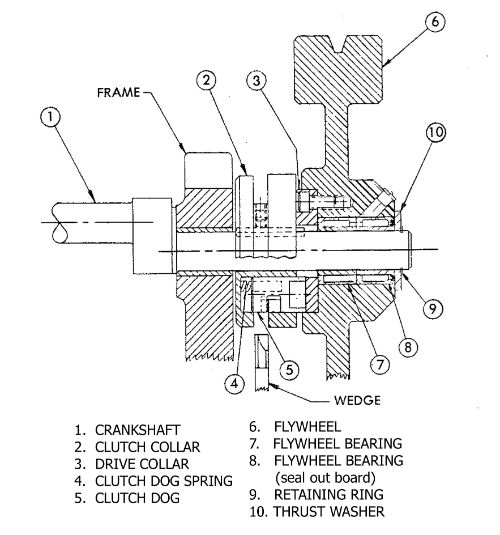

The pin clutch consists of a spring loaded driving dog that engages a slotted drive collar fastened to the flywheel. The dog is retained in a collar that is keyed to the crankshaft. In the free running position the driving dog is held back by a wedge. The wedge is fastened to one end of a spring loaded lever arm, on the other end is a solenoid. When the solenoid is energized by the anti-repeat control, it pulls up on one end of the lever arm. The wedge on the other end is pulled down allowing the driving dog to move toward the flywheel and engage the drive collar and the flywheel will turn the crankshaft. Before the crankshaft has turned one revolution the solenoid is de-energized and the wedge is pulled up by the lever spring. When the driving dog reaches the wedge, it will be forced back and out of the driving collar thus disengaging the flywheel from the crankshaft. The flywheel will continue to turn but the crankshaft will stop in a near-top position.