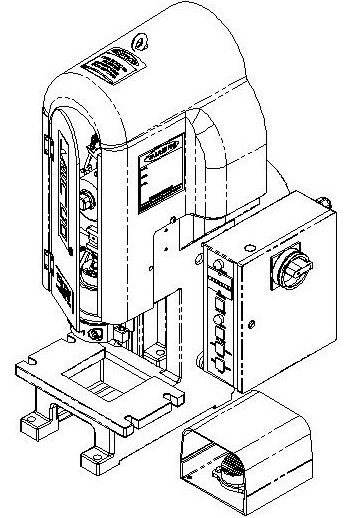

The Kenco Kompac press is a versatile, small press that provides a reliable, cost-effective choice for crimping, punching, blanking, forming, bending and stamping applications.

Available in a 3 or 5 ton model, Kompac presses are designed for fast set-up and operation in virtually any application or process. The "C" frame design makes die changes simple and fast, with larger throat and bed sizes to accept larger die sets. The flywheel and connecting rod are fully enclosed for safety, yet readily accessible for manual cycling and maintenance.

All Kenco Kompac presses have rugged, rib reinforced frames which minimize deflection and die wear for higher part quality and longer tool life. Fully ground "V" ways ensure accurate, consistent tool alignment. Our exclusive roller clutch is engineered of high strength, heat treated steel alloy for dependable high-speed, long-term operation.

Other standard features of the Kenco Kompac Press include:

|

|

3K Kompac |

5K Kompac |

|

Tonnage |

3 |

5 |

|

Speed [spm] |

300 |

285 |

|

Variable Speed |

option |

option |

|

Clutch Type |

roller clutch |

roller clutch |

|

Frame Opening |

7" |

7", 9" |

|

Throat Depth |

3.84" |

4.22" |

|

Standard Stroke Lengths |

1", 1.5" |

1", 1.5" |

|

Standard Ram Shank Diameter |

1" |

1.56" |

|

Flywheel [dia. x width] |

10" x 2.25" |

12" x 2.50" |

|

Flywheel Weight |

30 lb |

50 lb |

|

Motor |

1/3 HP |

1/2 HP |

|

Power Feed |

115V-1 Phase-60Hz |

115V-1 Phase-60Hz |

|

Bolster Plate |

.625" x 5.75" x 10.25" |

1" x 6.25" x 12.25" |

|

Floor Stand Weight |

40 lbs |

40 lbs |

|

Overall Weight |

190 lbs |

280 lbs |

Kenco also offers many options which will allow you to tailor the Kompac press to your specific manufacturing requirements. These include:

Contact Taber Industries today to determine which Kenco Press is right for you!